| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : ZHENGZHOUXINYU

Model Number : XY-ASC-60/65/70/75

Certification : GB/T19001-2016/ISO9001:2005

Place of Origin : ZHENGZHOUGONGYI

MOQ : 2T

Price : 425USD~580USD/T

Payment Terms : L/C, , T/T, D/P, Western Union, MoneyGram

Supply Ability : 1000/T/3D

Delivery Time : 4-6work Days

Packaging Details : Container bag

Size : 0-1mm,20%/1-3mm,30%/3-5mm,45%/5-8mm,5%

Refractoriness(degree) : 1750℃<Refractoriness<1850℃

Bulk density/ g﹒cm-3,≥ : 2.4~2.7 g﹒cm-3 (220℃,3h)

AL2O3 content(%),≥ : 60/65/70/75

SiC+C content(%),≥ : 14/15/16/18

Application : Slag runner and small blast furnace trough

Firing free ramming mixes for iorn trogh/Has a good slag erosion resistance and excellent thermal shock resistance

Product description:

This series of products are made of corundum,high quality bauxite and silicon carbide, and bonded by resins and tar. Installation can be done by ramming. The products are easy to be installed,pre-firing free,good slag erosion resistance and excellent thermal shock resistance.They can be applied to install and repair the iron trough of the balst furnace under 2500m3.

Category of Refractory ramming mixes:

Aluminium silicon carbide carbonaceous

Features:

The products are easy to be installed,pre-firing free,good slag erosion resistance and excellent thermal shock resistance.

Physical and chemical indicators:

| Brand | XY-ASC-60 | XY-ASC-65 | XY-ASC-70 | XY-ASC-75 | |

|---|---|---|---|---|---|

| Al2O3 /%,≥ | 60 | 65 | 70 | 75 | |

| SiC+C | 18 | 16 | 15 | 14 | |

| Bulk density / g﹒cm-3,≥ | 200℃ | 2.42 | 2.50 | 2.60 | 2.70 |

| Crushing strength / MPa,≥ | 200℃ | 15 | 15 | 20 | 20 |

| 1450℃ | 30 | 30 | 35 | 35 | |

| Firing linear change/ % | 1450℃ | ±0.6 | ±0.5 | ±0.4 | ±0.4 |

| Application | Slag runner and small blast furnace trough | Main runner, slag separator and runner of middle and small blast furnace | |||

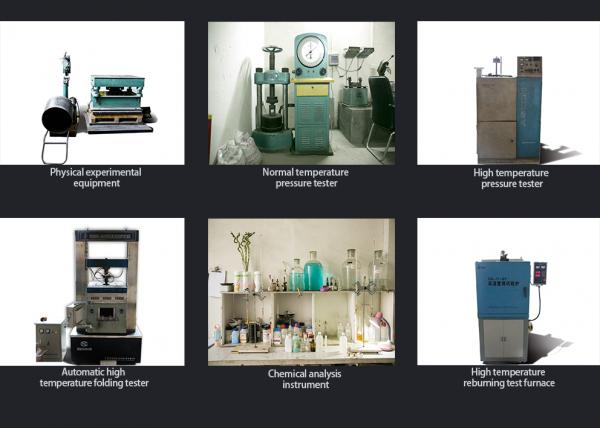

Production and inspection :

Packaging and transportation:

|

|

Firing Free Ramming Mix Good Slag Erosion Resistance Easy Installed Images |